Introduction

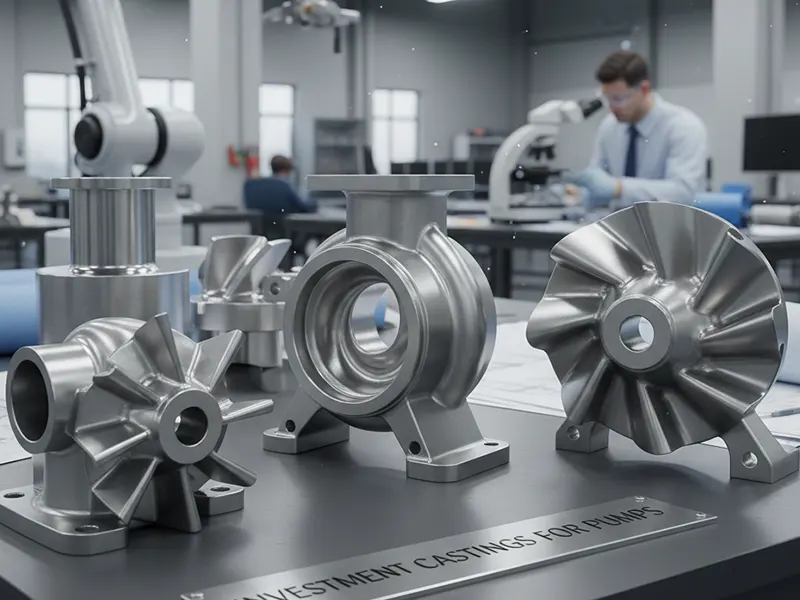

The right investment castings for pumps in centrifugal or submersible applications can be the difference between extended service life and premature failure, between productive performance and expensive downtime. When you're working with high-precision metal parts exposed to tough environments, every subtlety—microstructure of materials, gating design—counts. Based on the most current industry expertise and technical advances, this article presents a minutely detailed, reliable resource with practical application.

Engineering Requirements of Centrifugal & Submersible Pumps

Centrifugal and submersible pumps operate in very challenging applications—abrasive liquids, corrosive chemicals, high speeds, close tolerances, and continuous operation. That breaking up collection of stresses presents a strong argument for pump investment castings:

Complex geometries solved

Impellers, internal flow passages, thin vanes and intricate internal contours are possible with exquisite accuracy that other casting processes are unable to achieve.

High dimensional precision and consistency

Essential while balancing rotating assemblies and sealing close tolerances—precision frequently approaches within several hundredths of a millimeter, minimizing secondary machining requirements.

Improved surface finish

Smooth surfaces minimize fluidic turbulence, wear, and friction. Lower finishing translates into lower labor cost and increased throughput.

Material flexibility

From stainless steels to duplex alloys, even superalloys when necessary, without sacrificing mold fidelity.

Material Selection: The Metallurgical Foundation

Even the most accurate casting is only as reliable as its material selection—particularly for investment castings for pumps:

- Stainless Steels (e.g., 304, 316) provide good abrasion and corrosion resistance. Frequently utilized where there is water, chemicals or wastewater flows.

- Super-Duplex or Duplex Steels provide increased strength, superior corrosion resistance (particularly to chloride stress corrosion), and are best when aggressive fluids or saltwater environments are concerned.

- Bronzes or Copper Alloys can be selected for satisfactory cavitation resistance and worked-in lubrication characteristics.

- Alternative alloys can be used when high-temperature endurance or chemical compatibility is required.

In each case the casting process must preserve alloy integrity—minimize segregation, porosity and microstructural defects. That means process control, mold chemistry and gating design are critical.

Gating & Riser Design: Preventing Defects Under Turbulence

For centrifugal pump impellers particularly, microscopic flaws compromise dynamic balance and lead to high-cycle fatigue. Important considerations:

1. Gating systems need to provide free flow of molten metal, preventing turbulence that traps air or oxidizes the melt.

2. Riser and sprue need to be formed so that they feed shrinking sections and prevent internal porosity—computer-aided simulation tools are now employed to optimize these systems, increasing yield and defect-free product.

3. Mold orientation during casting does count—having a well-tilted mold aids feeding and solidification.

Making the most of these factors has been demonstrated to raise yield of casting over 50%, but significantly lower shrinkage or gas defects. So even for very complex investment castings for pumps, careful design translates to less scrap and greater dependability.

Dimensional Accuracy & Surface Detail

The signature of investment castings for pumps is precision:

- Characteristic dimensional tolerance is around ±0.1 mm for small parts, with typical surface finishes in the range 1–4 µm.

- Such a finish reduces secondary machining—essential in pump housings and impellers where fluid flow and close fits (e.g. wear rings, seals) require accuracy.

In submersible pump impellers and housings, this smooth precision decreases vibration, reduces turbulence caused by water, and guarantees maximum hydraulic efficiency.

Reliability in Operation: Corrosion, Cavitation & Wear

Pumps usually run under cavitating or erosive conditions. Investment castings for pumps have an advantage:

- Fine, homogeneous microstructures are more resistant to cavitation pitting than coarser cast types.

- Compact, imperfection-free interiors are more resistant to crack initiation and propagation and thus show better fatigue life.

- Corrosion resistant alloys combined with tight casting gives durable parts in aggressive or slurry environments.

Together these give longer maintenance intervals, less downtime and more economical operation over the long term.

Heat Treatment and Post-Casting Finishing: The Other Half of Performance

A freshly knocked-out investment casting might look ready for service but in pump applications the work is only half done. What happens after casting is just as important as the pour itself. In fact, for investment castings for pumps the right post-casting steps can mean the difference between a component that lasts a decade and one that fails in a year.

- Heat treatment isn’t just a box to tick. Solution annealing in stainless alloys, for example, dissolves the bad stuff and brings the steel back to its optimal corrosion resistant state. In duplex grades, it restores the critical balance between austenite and ferrite phases which is key to both strength and corrosion resistance. Skip it or do it poorly and the metal’s microstructure won’t stand up to real world service.

- Surface hardening comes into play where grit, slurry or cavitation are constant threats. Adding a wear resistant layer in just the right zones preserves the base material’s corrosion performance while giving those high impact areas extra armour.

- Precision machining and balancing might feel redundant when tolerances are already tight from casting but in pump hydraulics even a fraction of a “mm” can alter flow efficiency. Proper balancing also stops vibration from eating through bearings and seals prematurely.

- Passivation and polishing finish the job. Passivation chemically cleans and strengthens the protective oxide layer in stainless steel while polishing or shot-peening smooths out the microscopic stress risers and improves flow characteristics.

The truth is these steps aren’t “extras”. They’re the final touches that turn a well-cast shape into a dependable high performance pump part—built not just to fit but to last.

Design Flexibility & Prototyping

Another significant benefit of investment castings for pumps is design flexibility:

- 3D-printed wax or resin patterns speed up design cycles for new impeller or housing configuration.

- Complicated internal passages, undercuts, or patent-pending designs become possible without prohibitively expensive tooling.

- When the design is confirmed, mould tooling ramps economically to middle-of-the-line production levels, and is best suited to specialized submersible or custom centrifugal applications.

Cost, Volume & Total Cost of Ownership (TCO)

Investment casting investment in pumps needs to be analyzed in more than just initial marginal cost:

- Tooling expense is greater than sand casting, but pays for itself on moderate to high volumes.

- Suppressing machining stages and cutting scrap through precision casting significantly reduces costs-per-part.

- Extended service life, reduced failures, and less maintenance reduce cost of ownership over less accurate casting processes.

The outcome: a front-end premium often paid back within performance and uptime gains.

Quality Assurance & Casting Validation

Verification is important in high-risk industrial pumps:

- Non-destructive examination (ultrasonic, penetrant inspection, X-ray) confirms internal integrity.

- Dimensional inspections using coordinate measuring machines (CMM) verify as-designed tolerances.

- Balance testing is required for rotating parts such as impellers—precision casting reduces post-cast balancing requirements.

In each instance, investment casting control precision for pump castings is a value in providing quality results.

Environmental & Sustainability Benefits

Investment casting precision for pumps also aids in cleaner manufacturing:

- Less material waste as a result of low machining and high casting yield.

- Less energy used per part—manufacturing complex parts without multiple machining operations is energy-efficient.

- Reusability of ceramic shells is possible in most situations, reducing environmental effects even further.

These considerations are in line with contemporary manufacturing sustainability agendas.

When Does Investment Casting Overshadow Alternatives?

Balancing alternatives such as sand casting or die casting, investment castings for pumps are optimum when:

- Thin-wall features and complex geometry are necessary.

- High tolerances and excellent surface finish are essential.

- Moderate production runs make die casting not economical.

- Structural integrity, fatigue life, and corrosion resistance are most important.

- Rapid prototyping and tool flexibility are advantageous to custom or innovative designs.

A pump component may be so symmetrical and uncomplicated that sand casting might be adequate—but not often in most high-performance centrifugal or submersible configurations, where investment casting stands supreme.

Summary Table: Key Selection Factors

| Factor | Why It Matters in Investment Castings for Pumps |

|---|---|

| Material selection | Enables corrosion, abrasion, and fatigue resistance tailored to fluid contexts |

| Gating & riser design | Critical for defect-free integrity and increased yield |

| Dimensional & surface quality | Reduces machining, improves fluid performance, ensures reliability |

| Design flexibility | Supports prototyping and innovation with complex shapes |

| Cost vs. volume & TCO | Precision saves on capacity over operating life, not just initial cost |

| Quality testing | Precision casting supports high-level QA, ensuring deliverable longevity |

| Sustainability | High yield, minimal waste, energy-efficient manufacturing |

Conclusion: A Smart Choice, When Done Right

Deciding to go for investment castings for pumps is not just a matter of selecting the right product in the case of centrifugal or submersible applications; it is a decision that will bring you longer-lasting, better hydrodynamics, and operational reliability at your facility. The result of a well-engineered project (from alloy selection and gating design to surface finish and testing) will give you unexpected value: the pump parts will be able to resist abrasion, operate with low noise at high efficiency, and have a service life of more cycles with fewer maintenance interventions.

For premium pump makers looking for accuracy, material performance, and lifecycle economy, the smart way forward is to tap into the entire potential of investment casting—backed by expert process control, simulation-supported design, and strong QA norms.

Being an investment casting foundry company that believes in superior casting engineering, InovaCast Pvt. Ltd. is poised to cater to such cutting-edge requirements with tried-and-tested expertise and customized solutions.

+91-2827-252282 / 252283

+91-2827-252282 / 252283