One of Inovacast key capabilities is the manufacture, fabrication, and finishing of pump component castings, are one of the company's core competencies. Aluminium, stainless steel, carbon steel, and brass are some of the elements used in the casting of the pump elements. Pumps made from Inovacast castings are used in a wide range of applications, including centrifugal wastewater treatment pumps, fire pumps, submerged pumping systems, and sludge pumps.

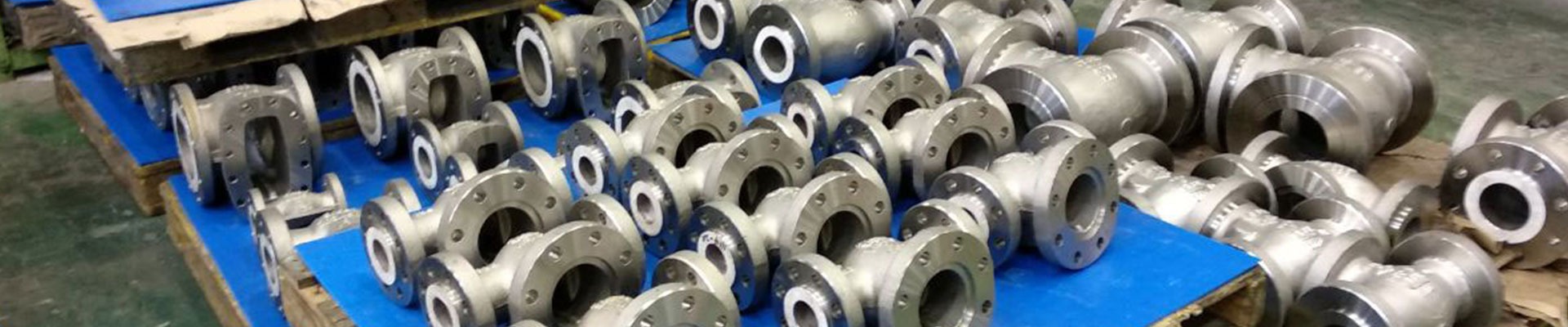

Inovacast produce a comprehensive variety of high precision components for use in valve applications as well as the pipeline fittings industry. Inovacast has a wealth of experience in delivering valve castings that meet or exceed all worldwide standards and requirements. Inovacast has experienced working with them who are specialists in a variety of valve varieties, pressure ratings, substances, and requirements provided by the company's clients. A number of renowned valve manufacturers are among the corporation’s clients. It has extensive expertise in the production of valve parts castings in various different conditions black, confirmation, and completed machine. The company has acquired expertise in the production of pressure tight castings that are completely sound, have tight dimensional accuracy, and have an outstanding surface polish, and so on. In order to preserve constant quality levels, metal analysis methods, as well as achieving long-term radiography standards of quality and ultrasonic inspections, are performed.

A wide range of valve castings are accessible for a variety of different types of valves including: gate valve castings, globe valve castings, swing pressure control castings, ball valve castings, and control valve castings. These valve fittings are available in steel material, carbide tipped, metal alloys, alloy wheels, and nickel entirely predicated alloy casting process.

Product Overview

The firm makes and processes big complicated castings for valves for use in a variety of sectors, including pump and valve manufacturing, cement manufacturing, chemical manufacturing, marine manufacturing, mining, power generation, and general engineering.

Benefits Of Purchasing Valve Parts Castings From Inovacast

- When it comes to castings for valves, we exclusively employ high-quality and well tested materials.

- Special alloys, such as duplex and super duplex steels, are also used.

- Items from our company are subjected to a variety of tests to ensure that only the most effective products reach our consumers.

- Our quality specialists are always working to improve the level of quality so that we can supply only the highest-quality valve castings to our customers.

- A diverse selection of items, each with a different weight, substance, and price

- Inovacast has a wealth of expertise in the design, manufacture, and delivery of investment castings for valves for a wide range of organisations, including large multinational corporations. Because valves are used in a variety of settings, we have invested in a highly sophisticated manufacturing facility that can produce a wide range of castings for both simple and intricate types of valves that are subjected to harsh and extreme conditions.

Valve parts castings is such an important component of every industrial valve, we, as casting suppliers for valves, use extreme caution while producing the castings. Our valves are thoroughly tested to eliminate the possibility of a disaster. Please do not hesitate to contact us if you have any questions concerning casting in general.

+91-2827-252282 / 252283

+91-2827-252282 / 252283